One、 Schematic diagram of broiler slaughtering and processing process

Hair chicken hanging → water bath anesthesia → assassination → bleeding → scalding → depilation → manual cleaning of small hairs → chicken hair water rushing into chicken hair collection room → claw cutting → hanging → opening → viscera removal → cutting head → carcass cleaning → precooling → carcass draining → viscera entering visceral processing room for treatment → carcass hanging → segmentation → sorting → sorting, weighing and packaging → loading → quick freezing → packing → refrigeration → sales

Two、 Slaughtering and processing technology of broiler

1. Chicken feed

(1) Before unloading, obtain the certificate of conformity issued by the animal epidemic prevention supervision organization at the place of origin, and observe the vehicle. If no abnormality is found, the vehicle is allowed to unload after the certificate and goods are consistent.

(2) The chicken cages with feather chickens are removed from the transport vehicle and placed on the hanging platform. The quarantine personnel conduct on-site inspection. The chicken cages with qualified healthy feather chickens are placed on the chicken cage conveyor and transported to the hanging room on the feather chickens.

(3) The hair chicken hanging room and the slaughtering workshop shall be strictly separated. The hair chicken hanging room shall be designed as dark as possible to avoid strong light exposure, resulting in excessive tension when the hair chicken flapping its wings.

(4) The chicken hanging personnel took out the feather chicken from the chicken cage holding the chicken belly, and then hung the two chicken feet on the hanger of the production line. Each chicken hanging staff can hang 800-1000 chickens per hour.

(5) The returned chicken cages are automatically transported into the chicken cage cleaning machine by the conveyor for cleaning, and the cleaned chicken cages slide to the chicken unloading platform through the chicken cage ramp.

2. Slaughtering and depilation of Broilers

(1) The main processes completed by the broiler slaughtering elevated transmission line are: hanging the chicken, water bath type hemp electricity, assassination, bleeding, scalding, depilation, claw cutting, hanging, etc.

(2) The overhead transmission line rack spacing: 6 inches (152.4mm), using standard drive chain, chain pitch t=25.4mm, variable frequency speed regulation, the design killing capacity of the production line is closely related to the linear speed of the production line, and the calculation formula of linear speed: linear speed = hourly output (only / hour) × Pylon spacing (m) ÷ 60 (min / h)

For example: design capacity: 3000 PCS / h, pylon spacing: 152.4mm

Line speed of production line: 3000 PCS / h × 0.1524 m ÷ 60 min / h =7.62 M / min.

(3) Water bath type anesthesia is usually used for live chickens. The anesthesia voltage is 70-90v and the anesthesia time is 2-3s. Or not through the hemp electricity process, the chicken is automatically transported for 1min through the overhead transmission line after hanging, so that the chicken can be stabbed after calming down.

(4) The bleeding time of the feather chicken after assassination is generally designed to be 3-4min. Scalding time: 40-60s, depilation time: 15-30s.

(5) Constant temperature ironing machine is used for ironing, and the ironing temperature is 58-62 ℃. Hang type depilation shall be adopted as far as possible to avoid infection caused by carcass contact.

(6) At 90. An automatic claw cutting machine is designed at the turning of the. The claw cutting machine is composed of a locating wheel, a drive and a rotating blade. After the chicken claw is cut, the chicken claw is unloaded by the claw unloader and placed in the collection vehicle.

3. To cut open the viscera

(1) The main processes completed by the broiler gut opening and evisceration elevated conveyor line include: gut opening, evisceration, head cutting, carcass cleaning, etc.

(2) The hook spacing of the overhead conveyor line: 8 inches (203.2mm), using standard drive chain, chain pitch t=25.4mm, variable frequency speed regulation.

(3) Put the extracted viscera into the visceral chute for inspection by the quarantine personnel. The qualified chicken carcass will enter the next process, the qualified chicken viscera will enter the visceral processing room for treatment, and the unqualified carcass and viscera will be put into a closed car and pulled out of the slaughtering workshop for treatment.

(4) The internal organs are separated. The chicken intestines are cleaned and sorted out and then put into the cold storage for cold storage. The chicken gizzards use the chicken gizzard degreasing machine to remove the grease on the surface of the chicken gizzards, and then the gizzard skin is peeled off by the gizzard peeling machine. After cleaning and sorting, the chicken intestines are put into the cold storage for cold storage.

(5) Eviscerate, the carcass must be cleaned before precooling to remove blood and water from the body.

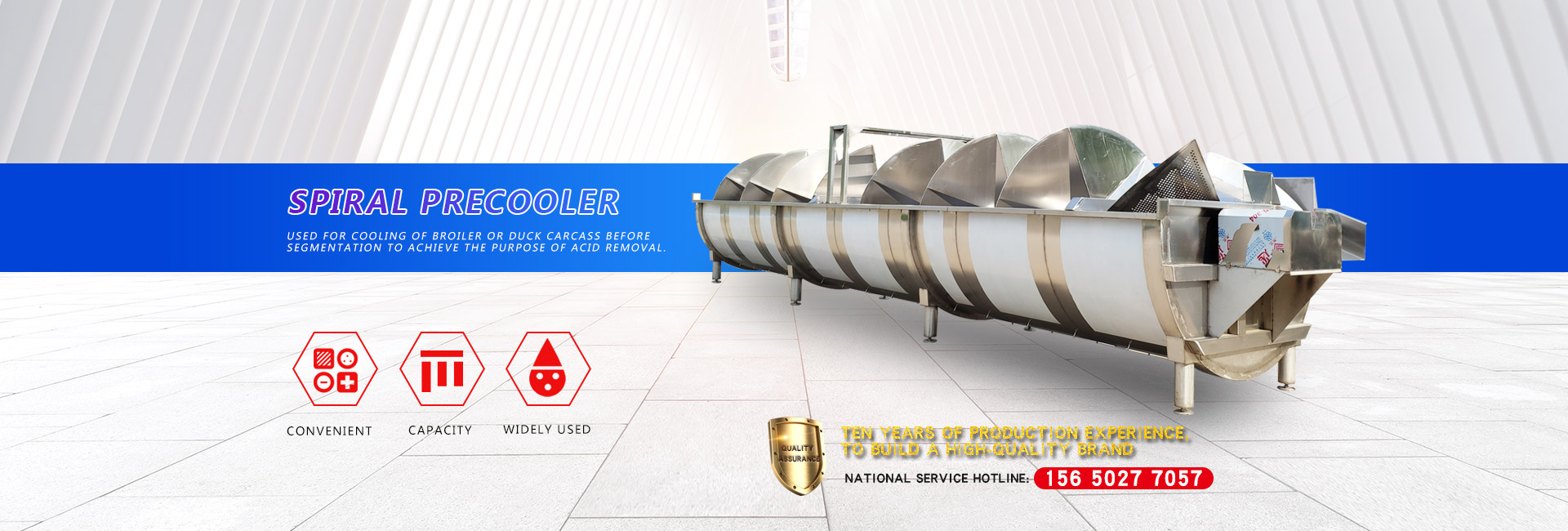

4. Precooling

(1) Precooling is divided into pool precooling and spiral precooling. The area occupied by pool precooling is larger than that of precooling by precooling machine.

(2) Precooling water temperature: 0-2 ℃, precooling time: 45min.

(3) The pre cooled carcass shall be drained by a dryer or an overhead conveyor line.

(4) The central temperature of pre cooled chicken carcass was below 10 ℃.

5. Split packaging

(1) The distance between hooks for dividing the overhead conveyor line: 8 inches (203.2mm), using standard drive chain, chain pitch t=25.4mm, variable frequency speed regulation.

(2) On the elevated conveying line, there are segmentation operators to segment the meat at different parts, and the segmented meat is transferred to the sorting station on the flat conveyor for sorting.

(3) Weigh the sorted meat and vacuum pack it according to the requirements, put it into the freezing tray, and use the cold meat trolley to push it to the freezing warehouse (-30 ℃) for freezing or to the finished product cooling room (0-4 ℃) for fresh preservation.

(4) Pack the frozen product pallets and store them in the refrigerator (-18 ℃).

(5) Temperature control of split packaging room: 10-15 ℃.